Strohm, a supplier of composite risers (TCP, its acronym in English), wants to double its bet in Brazil. After announcing the opening of an office in Rio de Janeiro and the intention to install a factory in the country as a result of the TCP Riser qualification process with Petrobras and Shell, which foresees the installation of a pilot project in deep waters by 2024, is now attentive to the revitalization of mature fields.

Although the TCP Riser concept is still directly linked to the pre-salt, Strohm is already negotiating with independent operators. “We are making quotes for jumpers and flowlines for some of these companies here in Brazil, but I think there is room to do a lot more if this starts to spread. We have product lines to serve the mature fields segment in a very effective way”, said the company's VP in Brazil, Renato Bastos.

Strohm offers three product lines, conceived to serve different applications. The first is composed of glass fibre with polyethylene. The intermediate product line, in turn, replaces fiberglass with carbon fibre and polyethylene with Nylon PA12. The third line, for High End applications, is a composite based on PVDF (polyvinylidene fluoride) polymer reinforced with carbon fibre.

“Our TCP is insensitive to corrosion and offers a reduced CO2 footprint by up to 60% compared to steel alternatives. Installation time is shorter, the material is lighter, and the supply chain is much leaner”, guarantees the Strohm executive.

JIP for the pre-salt

In the case of the JIP, Strohm will employ the High-End product line. It is not yet defined, however, in which area of the pre-salt polygon the technology will be piloted. The tendency is for the choice to fall on some asset where Petrobras and Shell are partners, but everything depends on the project schedule and the qualification of the riser.

The JIP encompasses four phases: materials qualification, development, engineering and the installation of the pilot pipes. It is also part of the process to define how the integrity management of the lines will be done. “With four years of duration, I consider it a structuring project, which has well-defined stages. The engineering centre in Brazil is the first step towards the installation of the factory”, stated Renato Bastos.

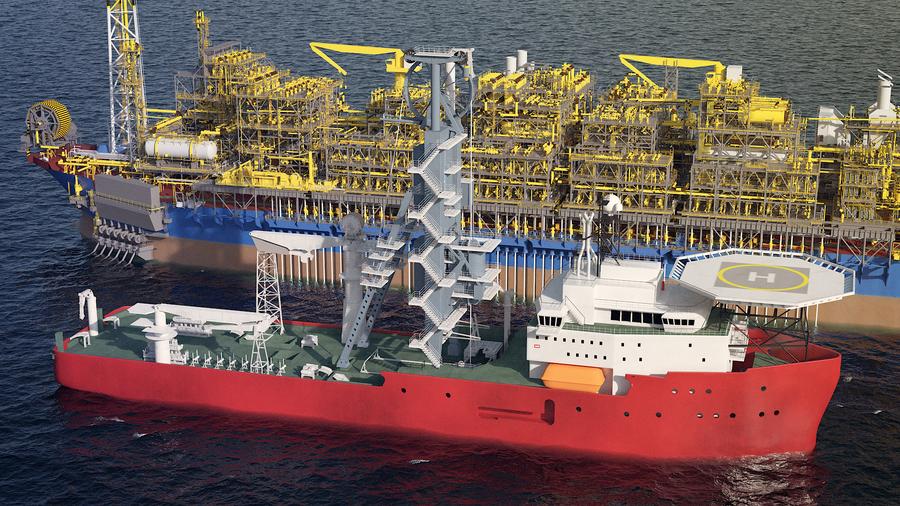

According to the R&D executive manager at Petrobras, Juliano Dantas, the challenging conditions of the pre-salt require the greatest number of qualified technologies. For this reason, says the executive, Petrobras has been developing its production systems capable of receiving any type of risers - rigid steel, flexible hybrids, hybrid risers, TCP or even bringing these technologies together in the same production unit.

“Currently, these types of risers have different qualification levels, but it is expected that in the near future all of them will be qualified”, said Juliano.

Please contact us for more information.