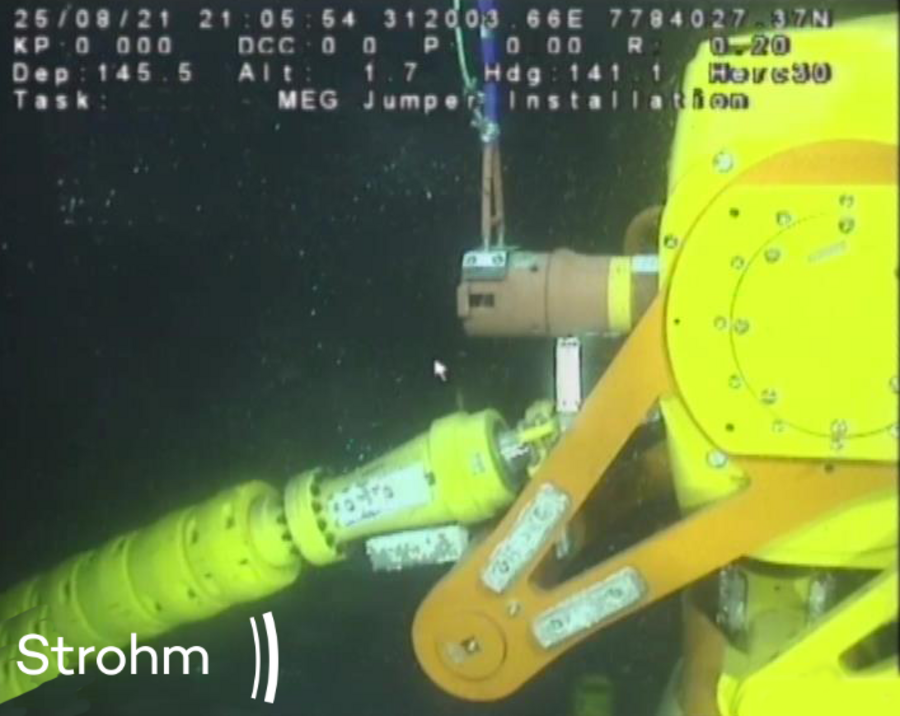

As part of the project, Strohm’s TCP Jumper technology is being utilised in Subsea 7’s project offshore North-western Australia.

Strohm’s TCP solution is 80% lighter in weight compared to its metallic equivalents, leading to improved transportation and installation costs. It is completely impervious to corrosion and has a high collapse resistance, offering a significantly extended service life. TCP’s manufacturing process also has a reduced manufacturing footprint, producing 50% lower CO2 levels compared to carbon steel pipe.

For TCP Jumpers such as those provided for Subsea 7’s project, a particular benefit is the elimination of offshore metrology requirements, leading to a considerable improvement on the cost and schedule risks associated with vessel standby and onshore rigid spool fabrication.

A logical step forward from the single jumper application is the Strohm “Jumper on Demand” concept whereby a long length of pipe is fabricated and stored on a single reel or cradle, ready to be cut and terminated in-country into individual jumpers as required.

There is a much wider world of advantages from implementing TCP in future projects in Australia and elsewhere. The cost-effective glass fibre polyethylene material used for Subsea 7’s project, is now complemented by carbon fibre polyamide and carbon fibre PVDF materials which are fully qualified for full hydrocarbon wellstream fluid applications in high temperatures. Furthermore, these materials are not susceptible to corrosion, blistering or embrittlement from carbon dioxide, hydrogen sulphide or hydrogen, making them particularly suitable for highly sour service applications, carbon sequestration projects and hydrogen transportation.

In addition to jumpers, TCP also has an established track record in flowlines and Strohm has recently embarked on a JIP project with Petrobras and Shell to qualify deepwater TCP Risers. This project is deemed to be a gamechanger for the industry as Strohm’s TCP benefits for deepwater applications include:

• Elimination of corrosion fatigue issues as there is no corrosion.

• Reduced riser top tension, contributing to a reduction in topsides payload.

• Smaller installation spreads and vessels facilitating reduced costs.

We are excited to be the first company to deploy TCP offshore Australia with Subsea 7. Now it’s only a matter of time before we see who will be the second Australian operator ready to reap the rewards of this rapidly growing technology.

Please feel free to contact us for more information.