Project description: The world's first crude oil TCP Flowline

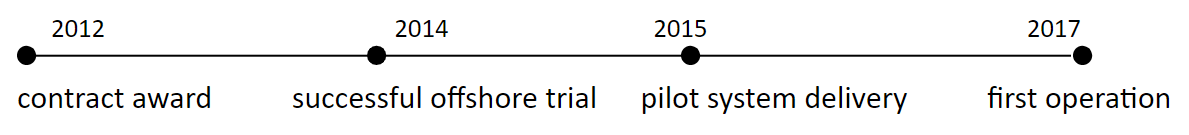

In 2012, Petronas Carigali contracted Strohm for the development & qualification of non-metallic, subsea flowline. Petronas have a large stock of corroding subsea flowlines that suffer from Sulphur Reducing Bacteria (SRB), or Microbacteria Induced Corrosion (MIC), for which Petronas seeks a solution in the form of taking the corrosion element out of the equation. The qualification program included, besides a variety of lab and prototype testing, full scale offshore installation testing. With successful completion of the whole program, a pilot flowline was installed in 2017.

Key system characteristics

Lower total installed cost:

- Fast installation

- Terminated offshore

- Single operation platform tie-in

- No divers

Lower total cost of ownership:

- No corrosion

- Less pigging

- No inhibitors, biocides pumping

Specifications

- Inner Diameter: 6''

- Pressure rating: 100 bar

- Water depth: 50 m

- Length: 500 m

Scope of Work

The Petronas pilot for a crude oil flowline was installed in West Lutong. Key project scope split in two main elements:

Platform to platform I-tube connection:

- TCP Flowline I-tubes on both platforms

- TCP pull-through I-tube, pipe termination onsite

- I-tube assembly lifted in place at both platforms

Pre-assembly of TCP Flowline and pull to install offshore:

- On-bottom stability through chain connected to flowline

- Tug-boat taking flowline to location

- Cutting of buoyancy to sink flowline, divers to connect flowline end-fittings to I-tube sections

Execution

Pilot project proved following TCP specific elements:

- TCP pull-through I-tube and onsite termination

- TCP on-bottom stability measure by means of chain

- Installation of the world’s first TCP for crude oil service

- Completing TCP Flowline qualification for Petronas

Contact us for more information about Thermoplastic Composite Pipe and its applications.