Project description

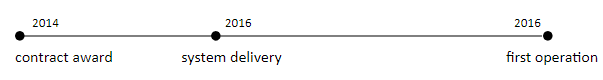

In 2014, Chevron Upstream Europe (CUE) started developing the High Pressure High Temperature (HPHT) Alder field in the Central North Sea. Alder is a gas condensate field which produces through a single subsea well in 152m of water. There is a requirement to inject methanol within the tree and wellhead tie-in spool downstream of the tree, leading to a requirement for a high pressure well jumper (12,500 psi). Strohm has been contracted to supply the high pressure flexible TCP Jumper, connecting the manifold with the tree.

Client (Chevron) conclusions & lessons learned, February 2017, Subsea UK

- Successful installation of world's first Thermoplastic Composite Pipe (TCP) in a permanent installation subsea worldwide

- Pipe in operation since 1 November 2016

- Successful joint effort involving Chevron, Strohm, Technip and Flowline Specialists

- Product more robust in handling than expected

- Installation from subsea carousel worked well

- Product weight vs stiffness managed during installation

- Involvement and input of Strohm at interface trials and transpooling key for success

- Concrete protection mattresses worked well for short length of TCP on seabed

Key system characteristics

- De-risking project schedule

- Manufactured in advance, terminated prior to installation on site

- Significantly more tolerance in length than rigid pipe

- Can be deployed using subsea pallet

- No metrology required, faster first oil

Lowest total installed cost

- Reduced fabrication cost

- Reduced buoyancy cost

- Reduced transport costs

- Reduced installation costs