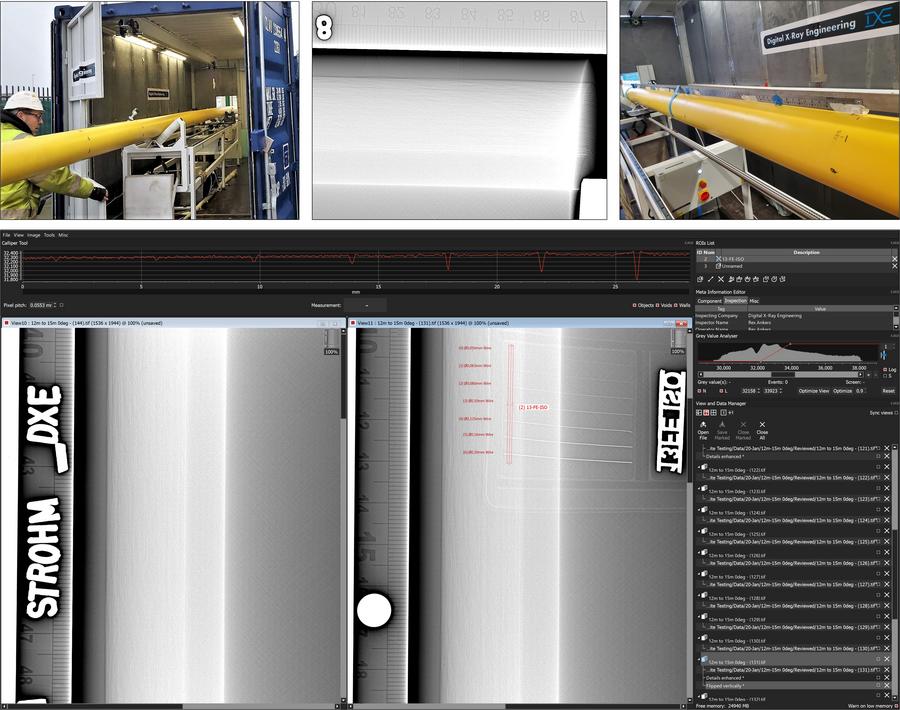

As we expand our qualified product range we also qualify the latest inspection technologies. We have been working with our development partner Digital X-Ray Engineering Ltd. to deliver an automated, highly sensitive digital X-ray system for use on our Carbon Fibre based designs for both PA12 and PVDF full pipe cross section mapping. The system developed by this specialist UK inspection company has the highest levels of sensitivity to identify even the smallest anomalies in the pipe construction.

This unique system gives us the ability to provide clients with a 100% pipe mapping overview, confirming the quality and performance of our manufacturing techniques and methods of construction. The system was used live for a first deliverable project late last year, performing a successful full scan of a Thermoplastic Composite Pipe (TCP) based on Carbon Fibre and PA12 polymer (CF/PA12). This inspection was a world’s first as a full TCP with 100% inspection coverage, first ever automated Digital X-ray on TCP, and record inspection volume collected on a single day. The technology has a significantly high rate of scanning speed capability and with this, the system proved its worthiness in all aspects and is ready for integration within the manufacturing facility.

Strohm has the largest track record of TCP in the world, with zero failures to date of pipe installed. As we continue to invest and develop its capabilities and production capacity; digital X-ray is one of the many enhanced Quality Assurance systems Strohm uses to ensure the robustness and quality of our ever increasing pipe product portfolio.

Please feel free to contact us for more information.