By Martin Van Onna, CEO, Strohm

Of all the energy transition efforts carbon capture and storage (CCS) has, arguably, the biggest job to do to win round its detractors. Funding pledges in the UK and Europe, while welcomed by industry, have faced criticism, and there is still scepticism from certain corners who see the technology as a “gamble”, one that shouldn’t be part of the net zero energy mix.

However, as countries across the continent race to zero out emissions by the middle of the century, every tool in the box will be required – not least CCS. While renewable energy is essential, it faces its own deployment, scaling and technology maturity challenges and it doesn’t hold the key to decarbonising certain sectors, like heavy industry and shipping.

As DNV’s recent Energy Transition Outlook (ETO) states, CCS is still developing and issues, including long-term storage, cost uncertainties, and limited economies of scale, are currently delaying its rapid deployment. Similarly, the IEA stressed this year that for CCS to play a significant role in the energy transition, it needs to swiftly scale up. Given the current average CCS project has a lead time of six years, accelerating timelines by three to four years is crucial.

Offshore storage sites are an ideal solution for permanently locking away emissions and in Europe, that means using the North Sea’s depleted gas fields. A report from global energy consultancy Xodus noted that by 2050, the volume of CO2 injected into the North Sea could match the amount of natural gas currently extracted from the region.

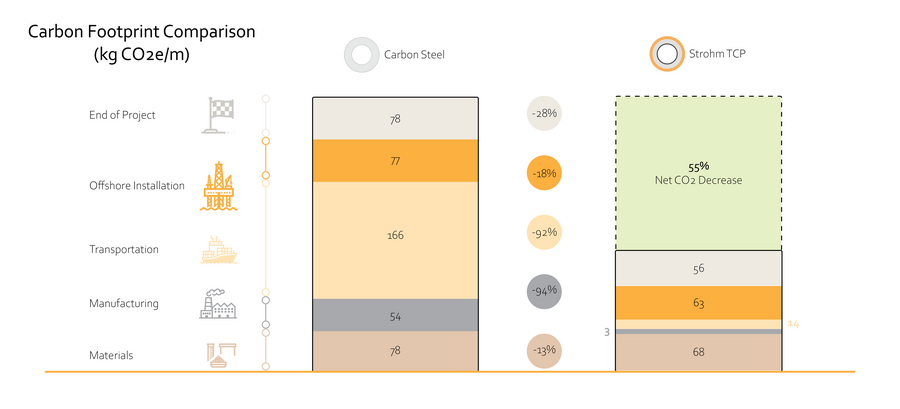

But for that to happen, Europe will need around 100 reservoirs, more than 7,500 kilometres of new pipelines and dozens of onshore emissions capturing and gathering sites. What’s more, major operational challenges offshore and onshore remain, most notably the issue of pipeline corrosion. Impure CO2 streams cause traditional steel pipelines to decay, but innovative solutions, like Strohm’s Thermoplastic Composite Pipe (TCP), offer a solution to this problem.

Onshore CO2 capture presents another challenge, as high concentrations of the gas often come mixed with impurities, like hydrogen sulfide (H2S). Purifying CO2 for transport through steel pipelines can be prohibitively expensive on a small scale. To address this, Transmission System Operators (TSOs) are planning to develop a smaller network using non-corrosive materials to gather CO2, which will then be purified centrally. TCP will be enabling for this process, allowing purification to occur at the required scale and pressure.

Once purified, large pipelines are needed to transport CO2 from land to offshore storage sites. These pipelines, typically made of carbon steel, require dry CO2 to prevent corrosion - especially in subsea systems where even a small amount of water can cause significant damage. Here, TCP offers a non-corroding solution by linking subsea manifolds to injection points, ensuring the final stages of transport are protected from corrosion.

It also presents industry with a chance to get grip on sulfur oxides and nitrogen oxides emissions, or SOx and NOx as they’re more commonly known. TCP’s corrosion resistance lowers the risk of these gasses leaking and eliminates the need for flaring, which is a significant source of SOx emissions.

Its lightweight design also reduces energy consumption during installation and operation, leading to less fuel use by compressors and engines, which in turn decreases NOx emissions. From a CCS standpoint, SOx and NOx are present in the exhaust fumes of power stations that burn certain fuels, wood for instance, and are a CO2 impurity – an issue for conventional steel pipes, but not TCP.

As decarbonization targets loom, it is crystal clear that the pace of CCS deployment must accelerate. Industry must adopt advanced, proven and qualified technologies like TCP to address operational hurdles, speed up execution, and make CCS more affordable. Red tape will also need to be cut in order to get projects off the ground and allow them to mature at a pace that keeps government CCS targets within reach. Though the sector is brimming with potential, it’s crucial to stay focused on overcoming the challenges that still lie ahead.

Publication: Carbon Herald