In a series of articles on sustainability, we consider how and where TCP plays a role in the Energy Transition. In the first article we looked at the footprint reduction of TCP compared to steel pipelines, the second article contemplated the suitability of TCP for CCUS applications, both static and dynamic. This third article will review the suitability of TCP for offshore hydrogen infrastructure.

As reported by the International Energy Agency [1], offshore wind has huge potential in a future hydrogen infrastructure. In their Sustainable Development Scenario, offshore wind becomes “the leading source of electricity in Europe and enables hydrogen to dramatically cut emissions from sectors such as iron, steel and shipping”. Hydrogen generation and offshore wind are a very good fit:

- It has the potential to increase the uptime of wind farms, by using the pipeline infrastructure as storage (cables can’t store energy)

- Green hydrogen especially has a good fit with offshore wind in the case of negative energy pricing [2]

- Electric power cables are the Achilles heel for wind farms, being vulnerable to damage and expensive to repair and very dependent on copper pricing

- 80% of offshore wind farms insurance claims are related to the cables, which is avoided by using pipes

While a good potential fit, today hydrogen still requires a lot of energy to be generated, and cost has to come down, while scaling up. Over the past few years, major offshore wind players such as Siemens Gamesa have been considering and developing all relevant technology solutions to enable cost effective offshore generation of hydrogen, which includes the electrolysis, power storage and compression of hydrogen, amongst other technologies.

Hydrogen and pipeline infrastructure: steel or TCP?

The infrastructure required for the future hydrogen volumes provides opportunities and challenges. Hydrogen can cause embrittlement of steel, reducing its pressure

containment capability as well as its fatigue resistance. Especially when considering hydrogen storage and the pressure fluctuations that are the consequence, as well as free-spanning issues with pipelines on the North Sea, the reduction in fatigue life of steel pipes is a serious challenge.

TCP provides an attractive alternative to steel for hydrogen transport:

- TCP does not corrode. In offshore hydrogen generation, condensation is a concernleading to corrosion risk for steel. TCP does not corrode and is clean and smooth.

- TCP has a superior fatigue life. Whether caused by pressure cycling or free-spanning issues, TCP’s fatigue life exceeds that of steel by far and it’s life is neverlimited due to fatigue.

- TCP has lowest total installed and LCOE cost. With low pressure and temperature ratings, Strohm developed the most competitive TCP solution.

- TCP has lowest total installed CO2 footprint. Proven in the field, Strohm’s TCP reduces CO2 footprint on an as-installed basis by 50% or more [3].

- In operation, TCP has lowest maintenance requirements and with that, the highest uptime.

Infield infrastructure for offshore wind farms: a plug and play integrated TCP solution

Strohm has a large track record of TCP Flowline installed offshore, whereby the TCP is pulled through offshore J-tubes and terminated offshore on a platform. Based on this

experience, Strohm developed an installation methodology for TCP that reduces installation cost and time, whilst providing a fully or mostly non-metallic solution from wind turbine to wind turbine:

- TCP can be installed using small multi-purpose vessels, using the proven horizontal lay method. Alternatively, installation methods currently used for electric power cables can be used as well with minimal adaptation required.

- TCP can be pulled through a J-tube and then terminated, providing a plug and playsolution with J-tubes only slightly larger than the pipe itself.

- TCP can be delivered in long lengths (on a reel or a carousel) and cut-to-length during installation. Alternatively TCP can be delivered in predetermined lengths for quick deployment

- Strohm provides TCP with a weight coating for on-target weight, ensuring on-bottom stability whilst allowing fast installation.

- TCP requires no maintenance and as such enables the un-manned concept of offshore hydrogen generation.

Figure 1: Offshore end-fitting installation of TCP

Figure 2: Installation and terminating TCP in a wind turbine generator

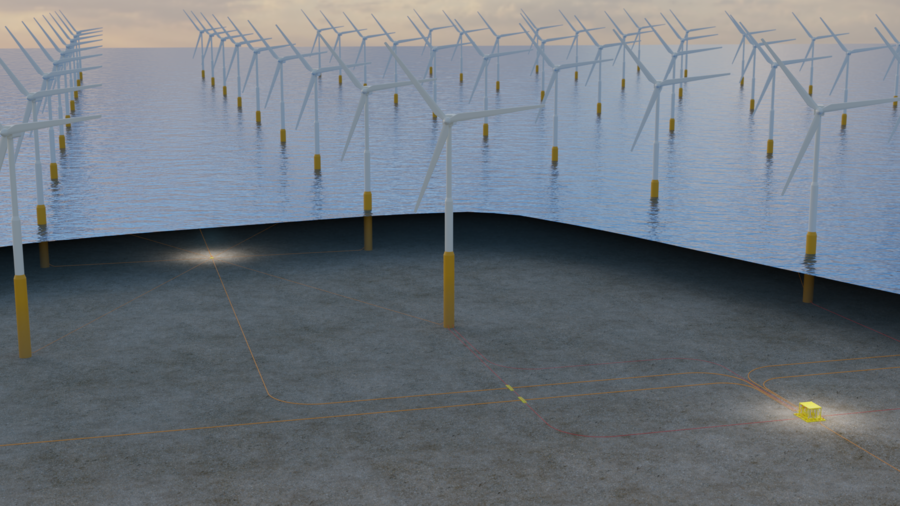

Developing the optimal offshore wind farm lay-out

Strohm is currently working on studies, investigating both the infield as well as export pipeline infrastructure for an offshore wind farm that generates 100% green hydrogen in a distributed setup. This means that every wind turbine generator will be connected to a TCP pipeline. As the installation is a significant part of the total installed cost of any offshore pipeline system, three layout concepts have been developed, costed and compared. Each concept may require different TCP solutions in term of size and/or pressure rating. As TCP maintenance is negligible during its lifetime, the optimum will be drawn up on a case- by- case basis, along the parameters of a) total installed cost b)

redundancy considerations, and c) total CO2 footprint estimate on total installed basis. Other parameters are considered on a case- by- case basis.

Figure 3: Field lay-outs for wind farms

Future developments:

Strohm is working on further developments that complete the plug & play concept of

offshore wind. Wish to learn more about TCP and hydrogen? Contact us!

[1] IEA Report: offshore_wind_outlook_2019

[2]Barclays report May 4, 2020: “Hydrogen – a climate megatrend

[3]Strohm technical note available on request