In a series of articles on sustainability, we consider how and where TCP plays a role in the Energy Transition. In the first article we looked at the footprint reduction of TCP compared to steel pipelines; in this second article, we consider the suitability of TCP for Carbon Capture Utilization and Storage, CCUS.

Industries around the globe are increasingly focusing on reducing the CO2 footprint of their operations. Part of this is done through e.g. increasing process efficiency, and green hydrogen, however there are still a number of “hard to abate” industries that will require carbon capture, utilization and storage as a primary way to reduce their footprint; some of the best known examples are the cement and steel making industries.

Carbon Capture, Utilization and Storage, CCUS, is one of the best ways to reduce large volumes of CO2:

- It can be realized relatively quickly.

- It is cost effective, especially when done at scale.

- There is potential in usage in greenhouses.

In Europe and elsewhere a number of projects are ongoing for offshore and subsea carbon capture and storage in old depleted reservoirs; here, there are no concerns around storage of CO2 as there are in onshore fields, the wells are available and platform infrastructure is available. The pipeline infrastructure is often not suitable for the highly corrosive nature of CO2: this is where TCP comes in.

Strohm has been investing in the development of TCP solutions aimed at CCUS, with a particular focus on offshore subsea pipelines. The main elements that make TCP a particular interesting solution for CCUS will be covered in this article. These elements are: total elimination of any corrosion, the ability to pull TCP through old pipelines, fast and robust termination in the field and the fact that TCP is a durable pipe, lasting 20 to 30 years.

Pulling TCP through existing pipelines

Especially in land approaches it can be highly effective to use larger, old gas pipelines as a conduit to pull through a new flowline to carry CO2 to the depleted offshore gas reservoirs. In such case the CO2 carrying flowline is pulled through the existing pipeline, eliminating the need and associated cost of a separate and dedicated land approach.

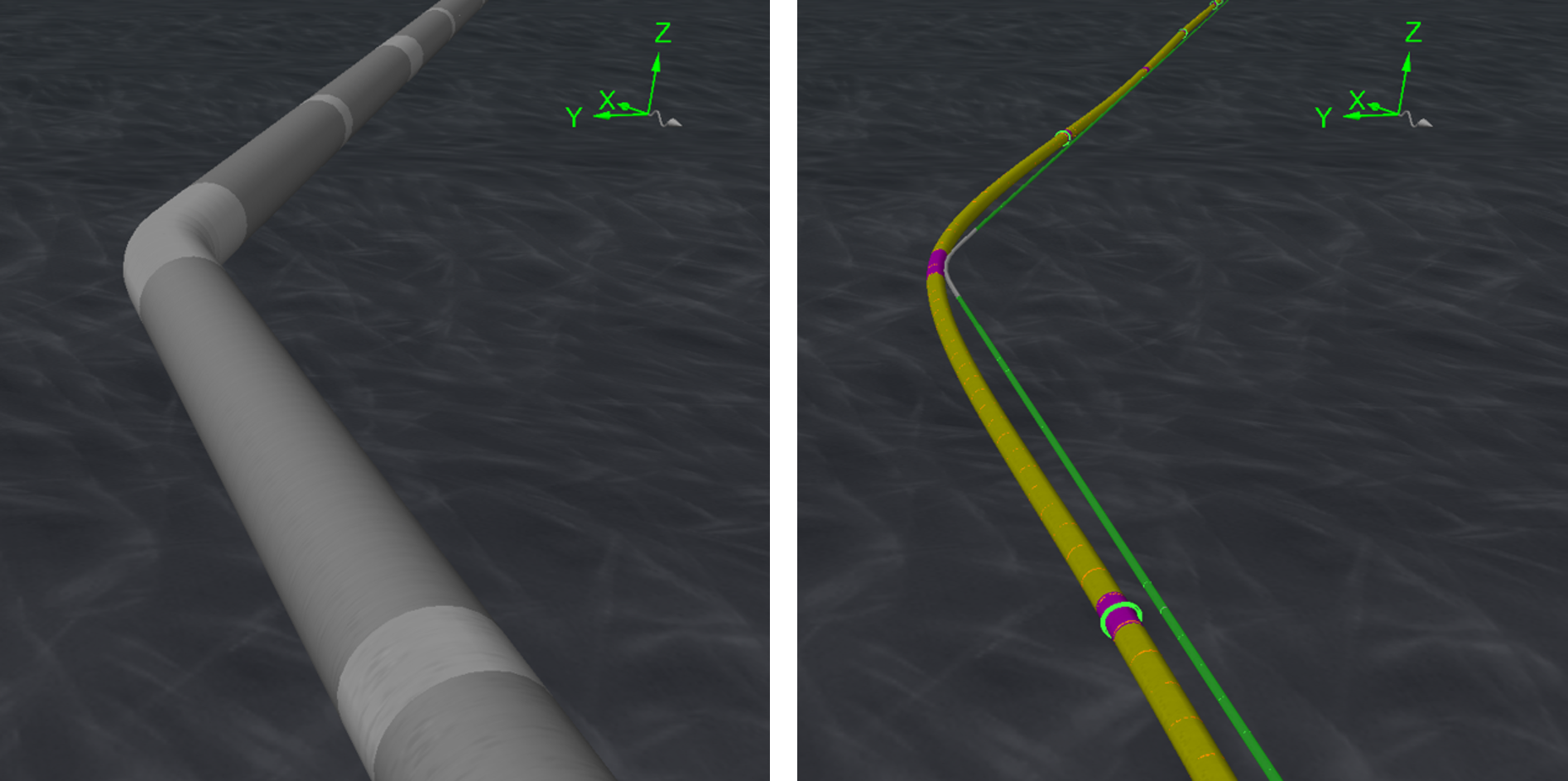

In Strohm we have done several studies into pulling through TCP through existing pipelines, which include small bends (often around “4D” bends, bends with a radius as small as 4 times the diameter of the pipeline). An example is shown in Figure 1. These studies have shown the potential of pulling TCP through old steel pipelines, even when the steel pipeline is old and corroded, leading to high levels of expected friction. The TCP pull through shows that:

- The TCP can navigate most bends in an installed pipeline. Strohm performs detailed assessments on pipeline pull through, whereby the strains are assessed in the bends, and verified not to exceed allowable levels.

- By using air, the TCP can float inside the existing pipeline which leads to very low friction on the TCP during pull through. Depending on the length of the pull through, a wire rope can be used to enhance the pull.

- As TCP can be manufactured in single lengths of 3 to 6 km of pipe depending on size, very long pipe pull throughs can be executed without requiring intermediate intervention in the pipeline.

- TCP can be terminated in the field as will be outlined later in this article, which means that the TCP can be pulled through without the end fitting, making pull through much easier.

Figure 1: Simulation of TCP pull through steel pipe bend. Yellow line is TCP, green line is wire rope

Termination in the field

In Strohm we have a lot of experience in installing the end fitting at location, whether onshore or offshore, and whether in vertical or in horizontal position. In particular for the CCUS application, this translates in easier pull through and lower cost:

- The TCP can be pulled through pipelines or J-tubes that are only slightly larger than the TCP outer diameter itself. This means that offshore platforms do not require any modifications to the riser or J-tubes to bring TCP up to the platform, which is a huge cost reduction.

- The termination in the field provides ultimate flexibility in determining the actual length – at the point where it is required, providing flexibility and project de-risking.

- It is much easier to pull through a pipe through bends, with no end fittings installed.

Strohm can perform end fitting installation ourselves, or alternatively, train our clients and partners to perform this operation. Figure 2 shows an end fitting installation completed offshore West Africa.

Figure 2: Offshore pipe termination after TCP pull through J-tube

TCP: an extremely robust pipe

When pulling a conventional flexible pipe through an old, existing pipeline, there is an increased likelihood of rupturing the outer coating (also called “outer sheeth”) which will lead to damage of the flexible pipe; the outer coating is not connected to the rest of the pipe structure and is therefore easily damaged.

Contrary to conventional flexible pipe and RTP (Reinforced Thermoplastic Pipe), the outer coating of a TCP is melt-fused to the rest of the pipe structure forming a solid, durable wall. Combined with a high scratch resistant coating, TCP is a durable system that is ideal for pipeline pull through.

Elimination of any corrosion

CO2 is known to be a very corrosive fluid, especially when contaminated with other constituents such as water. This mix leads to an extremely corrosive environment which causes rapid corrosion on carbon steel. TCP therefore is, especially from a corrosion stand point, well suited for CO2 transport:

- Our current TCP qualifications already cover CO2 exposure and as such is qualified for CO2 transport already.

- TCP is non corrosive which includes CO2 – even in combination with seawater, a lethal mix for conventional flexibles, TCP is insensitive to CO2.

- TCP is designed for higher pressures and as such can handle all pressure regimes that are anticipated for CCUS.

Wish to learn more about TCP for CCUS applications? Contact us.