Despite its huge potential as a means for decarbonising hard-to-abate sectors, carbon capture and storage (CCS) still has its detractors. Some see it as a distraction that is using up capital that would be better spent on boosting electrification and green hydrogen production, thereby avoiding emissions altogether. What has become clear though is that countries must use all the tools in their arsenal to hit net zero, and that includes CCS. Electrification and green hydrogen will of course be vital too, but they have their own unique challenges that are putting the brakes on deployment.

Hitting mid-century net zero targets demands a mammoth effort and while the IEA’s latest report on the subject finds that CCS will be key to the energy transition, it also says the technology must scale up and accelerate. If all planned projects are delivered, some 420 megatonnes of CO2 a year (MtCO2/annum) will be captured in 2030, more than eight times current capacity. But that’s less than half of the 1 gigatonne of CO2 a year (GtCO2/annum) required for the Net Zero Emissions by 2050 Scenario (NZE Scenario). Current project lead times average six years, but that’s no longer acceptable and by adopting best practice, there is scope to reduce this by around three to four years.

For storage, offshore locations are ideal for permanently locking away emissions; in Europe, the North Sea basin, with its countless depleted gas fields, is the perfect home for large volumes of CO2. In a report released last year, global energy consultancy Xodus said: “The volume of CO2 being injected into the North Sea by 2050 will be equivalent to the natural gas currently being extracted from the basin. That scale of carbon capture, utilisation and storage will require some 100 reservoirs, more than 7,500 kilometres of new pipelines and dozens of onshore emissions capturing and gathering sites.”

There are still operational challenges to overcome though, both onshore and offshore, and especially around the issue of corrosion. Strohm’s Thermoplastic Composite Pipe (TCP) offers an answer to this challenge as it doesn’t corrode, while the product’s flexibility streamlines the offshore installation process, meaning projects can progress more quickly.

On the issues with onshore capture, CO2 is well known for its corrosiveness when contaminated. Where capture is carried out at locations with a high concentration of CO2, the resulting gas often carries with it a range of impurities, like hydrogen sulfide (H2S). Purifying CO2 so that it can travel through steel pipelines is extremely expensive, especially when done on a small, individual scale. As such Transmission System Operators (TSOs) plan to use non-corrosive materials to develop a smaller gathering network, before purifying CO2 en masse before it is sent to larger transmission lines (Figure 1 and 2). For this to be successful, TCP will be key as it doesn’t corrode, meaning purification can be done centrally, and can operate in the pressures and sizes required.

Figure 1: Central purification

Figure 2: Distributed purification

On the offshore and subsea side, large pipelines are needed to export CO2 from shore to the reservoirs and aquifers. These pipes tend to be carbon steel and require dry CO2. Here, the issue is around infield infrastructure in systems that use subsea wells and valves, where even the tiniest bit of water can spark major corrosion challenges. By using TCP to link manifolds to injection trees, meaning the last mile of transport is fully non-corroding, it again can provide the solution.

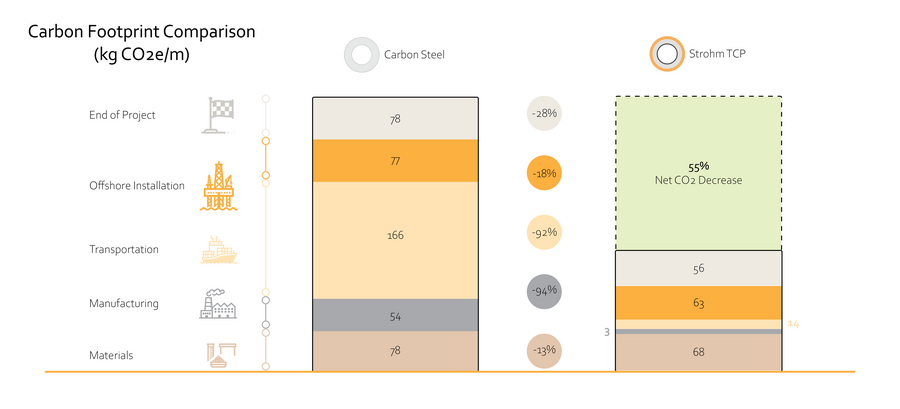

Flexible pipes also simplify the offshore installation process, slashing project lead times, a must for the NZE Scenario. Moreover, TCP is lightweight enough that developers can use small vessels, further accelerating offshore project execution and reducing the environmental impact of delivering CCS. There is evidence to back this up too and research carried out by DNV has shown that TCP can reduce the total carbon footprint of a given offshore pipeline solution by more than 50% ( Figure 3).

Figure 3: Carbon Footprint reduction

There is little doubt that the scale and pace of deployment of CCS must significantly increase to keep decarbonisation targets within reach. In turn industry will need to embrace technologies like TCP to overcome operational challenges and speed up project execution, while ensuring sequestration is affordable. It is unquestionably an exciting time for the burgeoning CCS sector, but we mustn’t let this excitement distract from the gaps that still need to be bridged.

By Martin van Onna, CEO, Strohm