Thermoplastic Composite Pipe (TCP) is sometimes referred to as “non-metallic pipe”, or NMP, as a way of describing what it is not. The background for this interesting description is to make it clear that TCP does not corrode.

In this article we explore what this attribute of TCP actually means for E&P companies, both in operating benefits and the knock-on infrastructure and installation cost savings. At Strohm, we learn a lot from working with our clients who are embracing TCP for flowline applications around the globe.

Corrosion and its effects on pipeline infrastructure

Corrosion exists in many shapes and forms and is not always fully understood. Corrosion leads to reduction of the wall of steel pipelines and eventually to leakage with oil spills as a result. Water injection or chemical injection may lead to an increase in corrosion rates due to production becoming more sour, or due to micro bacteria that attack the hydrocarbon production lines.

Today, around 50% of oil spills in the world are the result of pipeline corrosion. The most important measure to protect pipeline infrastructure against corrosion is by injecting corrosion inhibitors into the pipeline; these inhibitor injection systems need to have an uptime of 90% or more to be effective. Typically, for every month that an inhibitor system is down, the operator loses one year of the pipeline’s service life. To assess the state of the pipeline, they require regular pigging which leads to loss of production.

Direct benefits of no corrosion

With TCP being non-corrosive, the operator immediately removes the risk of pipeline leakage and avoids the cost of corrosion prevention measures. This includes:

- No more storage, and pumping of corrosion inhibitors

- No more corrosion related pigging and the related deferment of production

- No more leakage and oil spills as result of pipeline degradation

The direct result is highest pipeline infrastructure uptime, no production deferment and lowest operating cost, leading to lowest total expenditure.

Knock-on benefits

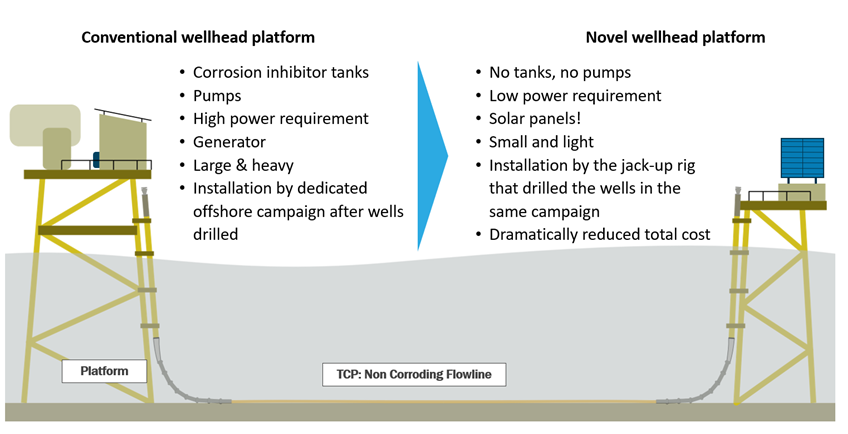

We are working with operators that are taking the benefits of no corrosion a step further, by designing field architectures and assets around the total lack of corrosion. This leads to a further dramatic reduction in total installed cost and total life cycle cost. Some examples:

- The lack of corrosion inhibitors means that there is no need for inhibitor storage tanks or injection pumps

- The lack of pumping requirement reduces the anticipated power requirements

- Lower power requirements enable replacement of the power generator with solar panels

- The platform becomes small and lightweight in a positive snowball effect

- For shallow water wellhead platforms, the lightweight platform can be installed using a jack-up rig and does not require a dedicated vessel for installation

With TCP being fully qualified, installed and having achieved Technology Readiness Level 7 (TRL 7) recently, we are working with operators ready to take full advantage of what TCP does not do: corrode.

Contact us for more information on the benefits of TCP.